Dr. Thorsten Schmidt, CEO of HELLER, succinctly summarizes the new direction: “Mechanical engineering is a thing of the past. Today, it's about how we combine experience, technology, automation, and digital intelligence in a way that creates real added value for our customers. Together with our partners, we want to design manufacturing that is not only productive, but also intelligent and future-proof.”

Strategic importance of EMO 2025

EMO Hannover has always been the leading trade fair for international mechanical engineering. For HELLER, however, participation in 2025 means more than just a presentation platform. It is the starting point for a new brand strategy, a milestone on the path from machine manufacturer to holistic solution provider. EMO is the place where this transformation becomes visible – visible in the machines, in the automation solutions, in the digital services, but above all in the attitude with which HELLER presents itself. The company is demonstrating that it is ready to take responsibility and actively lead the industry into the future.

Thorsten Schmidt sums it up: “With ‘Experience sparks Intelligence,’ we are showing that HELLER is much more than a machine manufacturer. We see ourselves as a partner for productivity, a driver of innovation, and a companion for our customers on their journey into an intelligent future. This attitude shapes our presence at EMO – and beyond.”

Machines and automation – the symbiosis of precision and efficiency

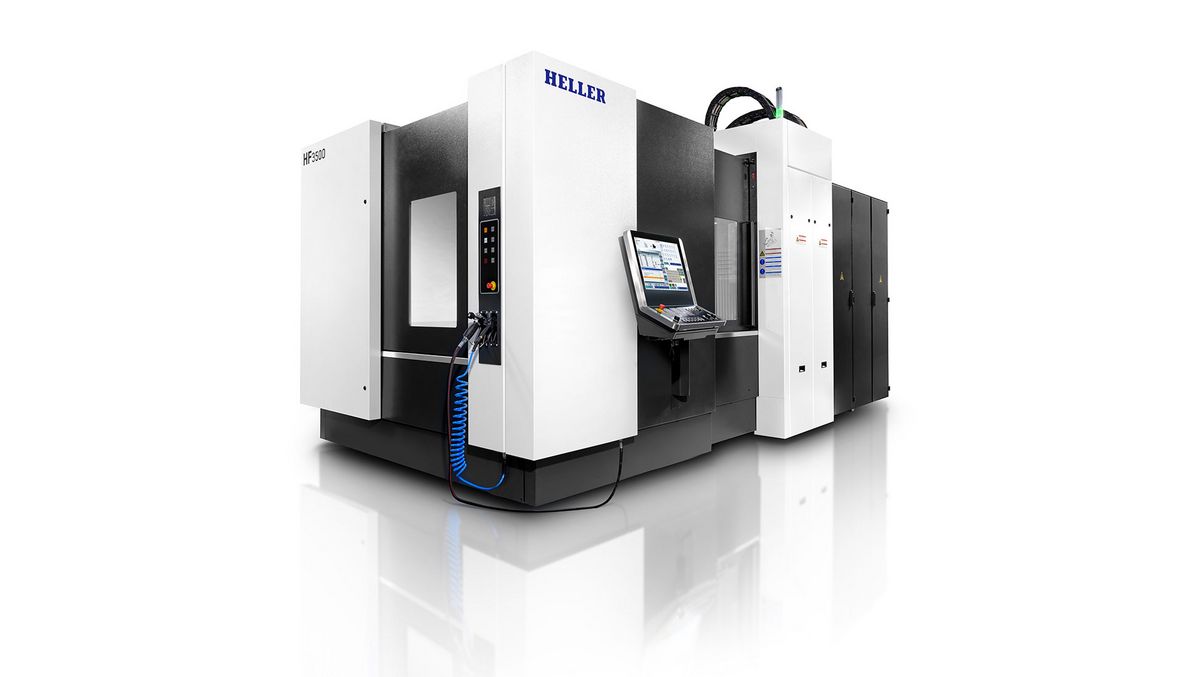

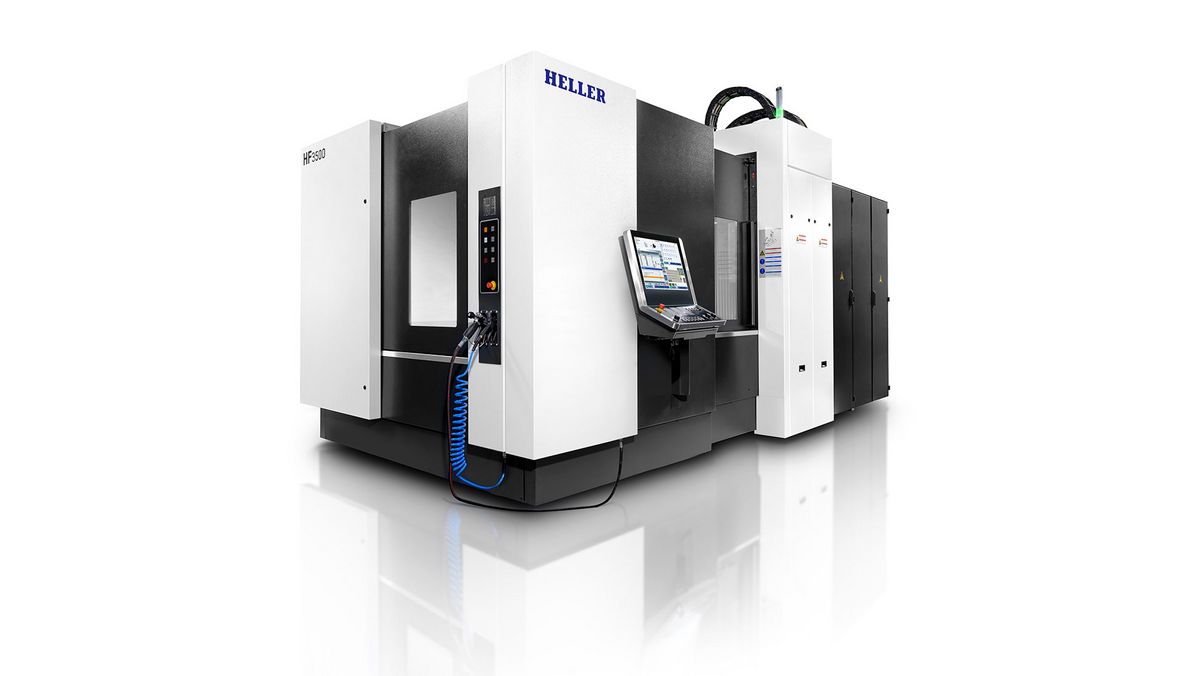

A key highlight of the trade fair presentation is the HF 3500 in combination with the new RP4 robot cell. This system exemplifies HELLER's philosophy of viewing automation not as a complicated add-on function, but as an integral part of modern manufacturing. Thanks to its multibatch capability and intuitive teach concept, a wide variety of workpieces can be set up flexibly without the need for special robot expertise. The integrated digital twin supports the operator during setup and simulates processes before they are actually executed. The result: setup times are reduced, sources of error are minimized, and even unmanned shifts or autonomous weekend operation become possible. Thorsten Schmidt emphasizes: “Our customers are under enormous pressure. They have to manufacture increasingly complex components in smaller batch sizes with shorter delivery times, while at the same time facing a shortage of skilled workers. The HF 3500 with RP4 is our answer: an automation solution that is simple, flexible, and economical.”

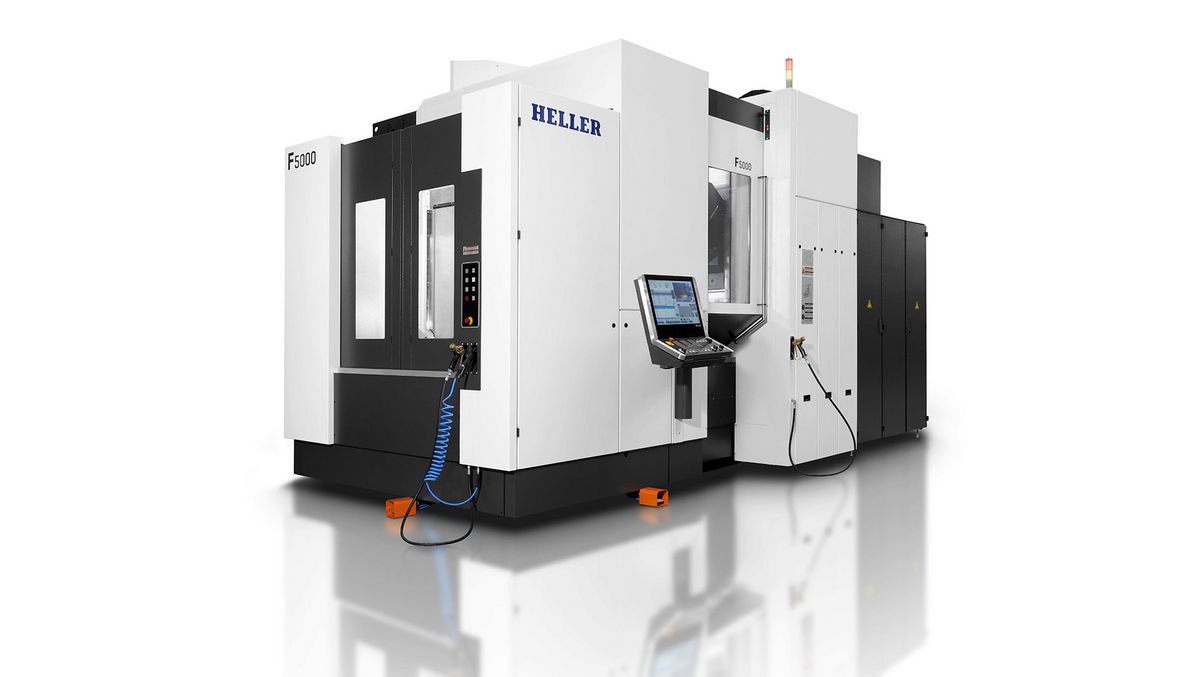

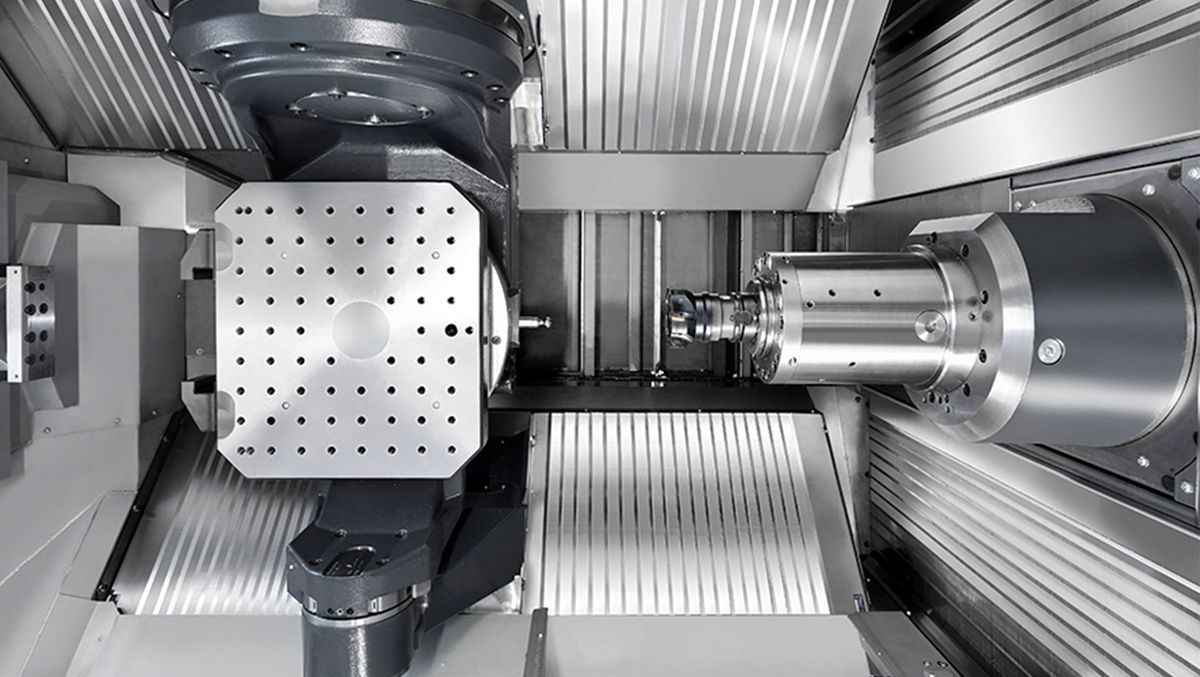

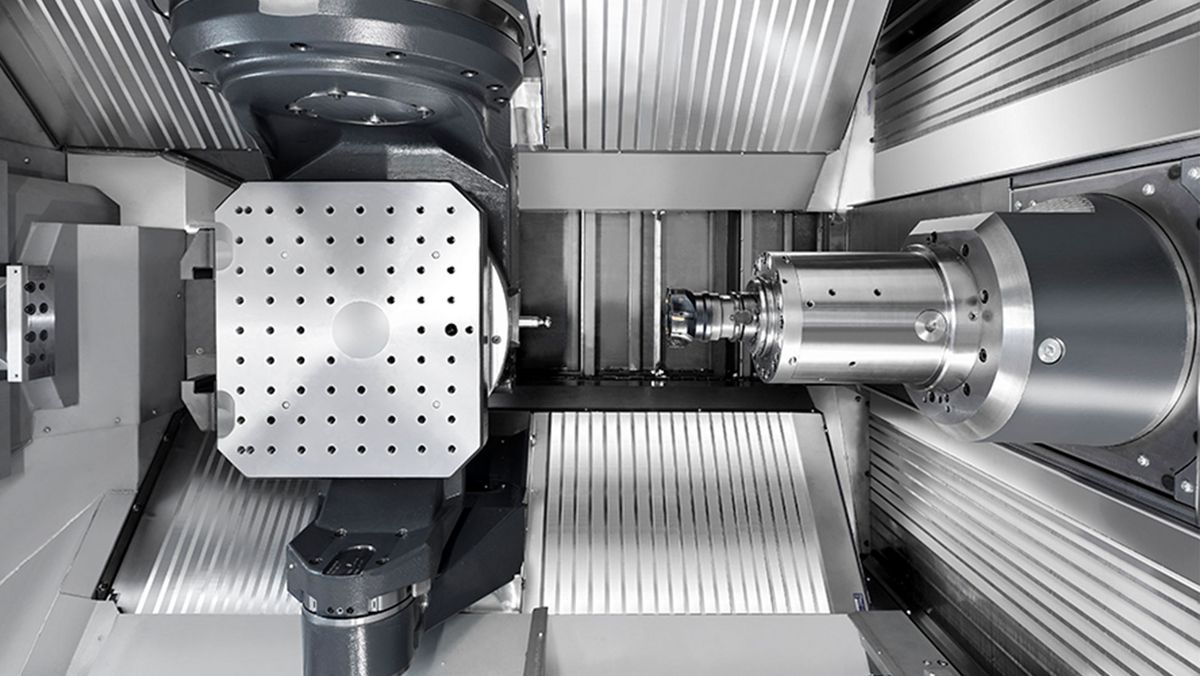

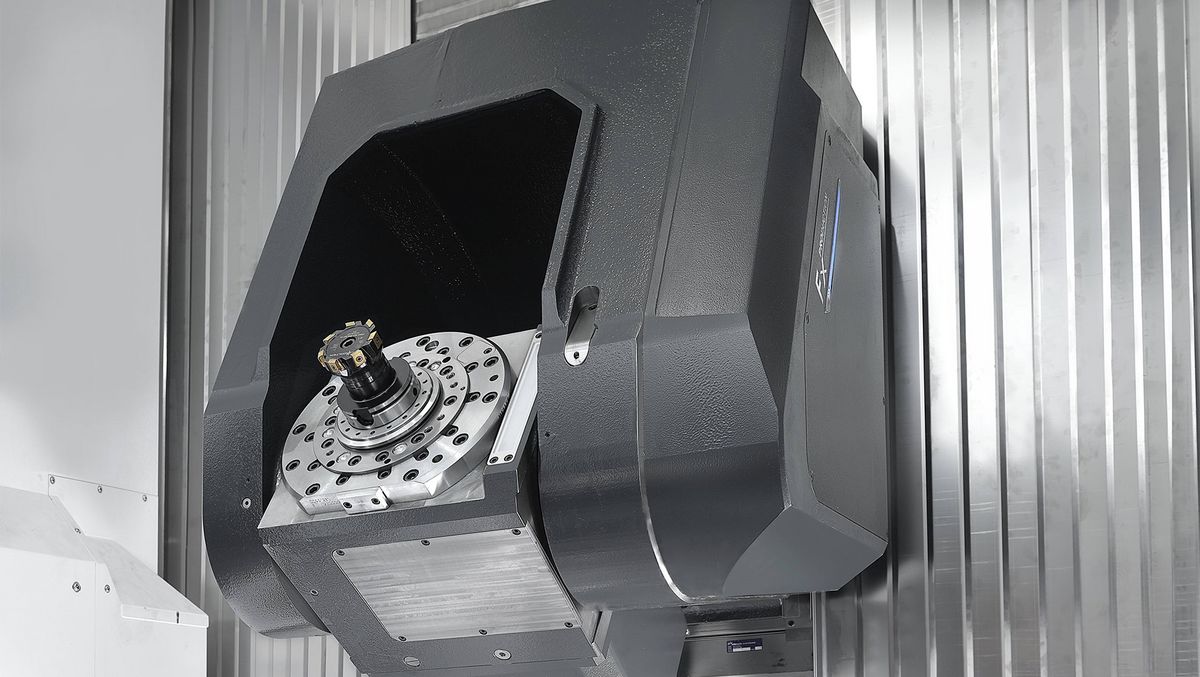

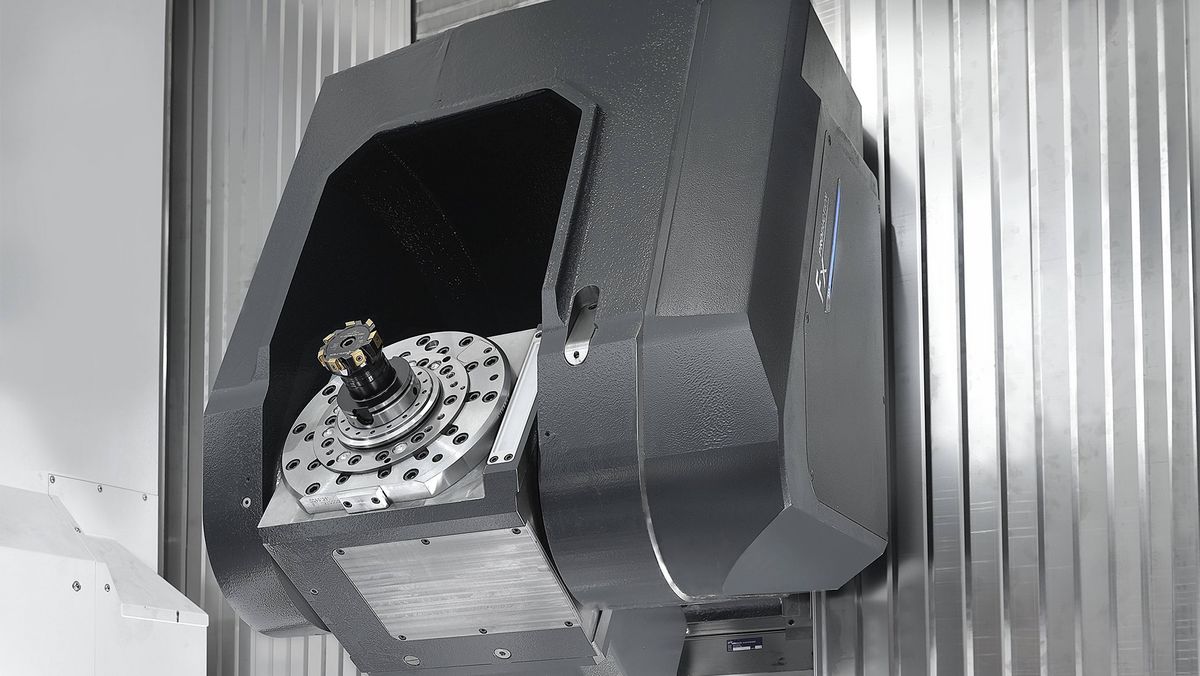

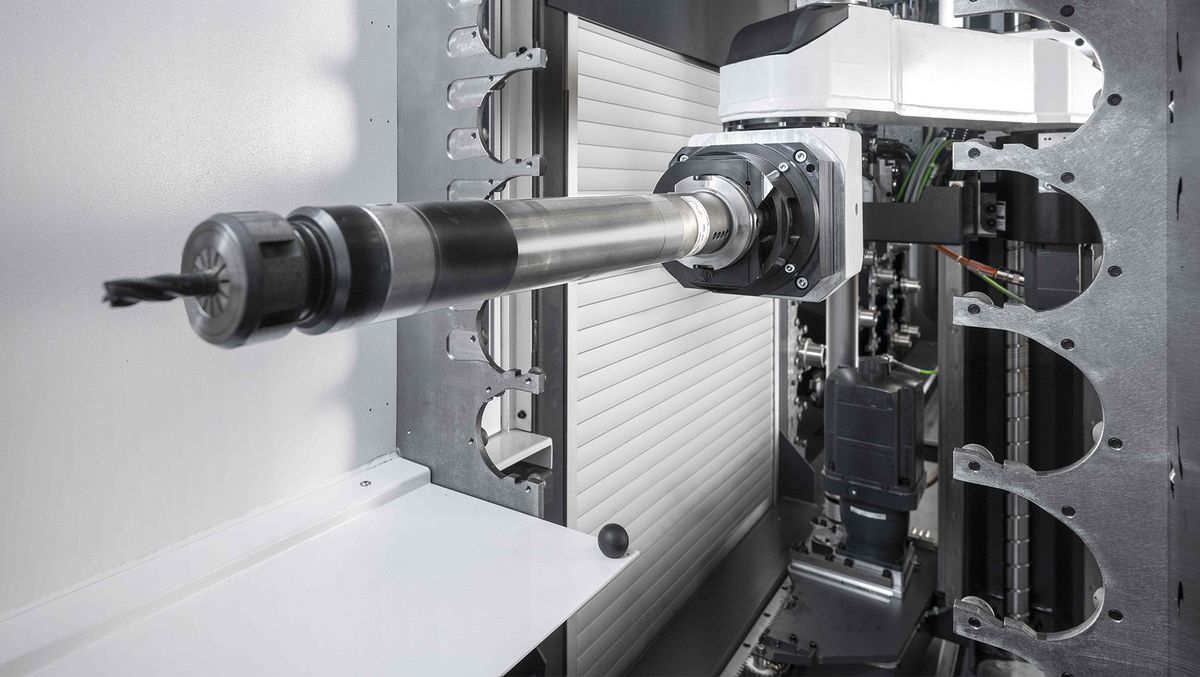

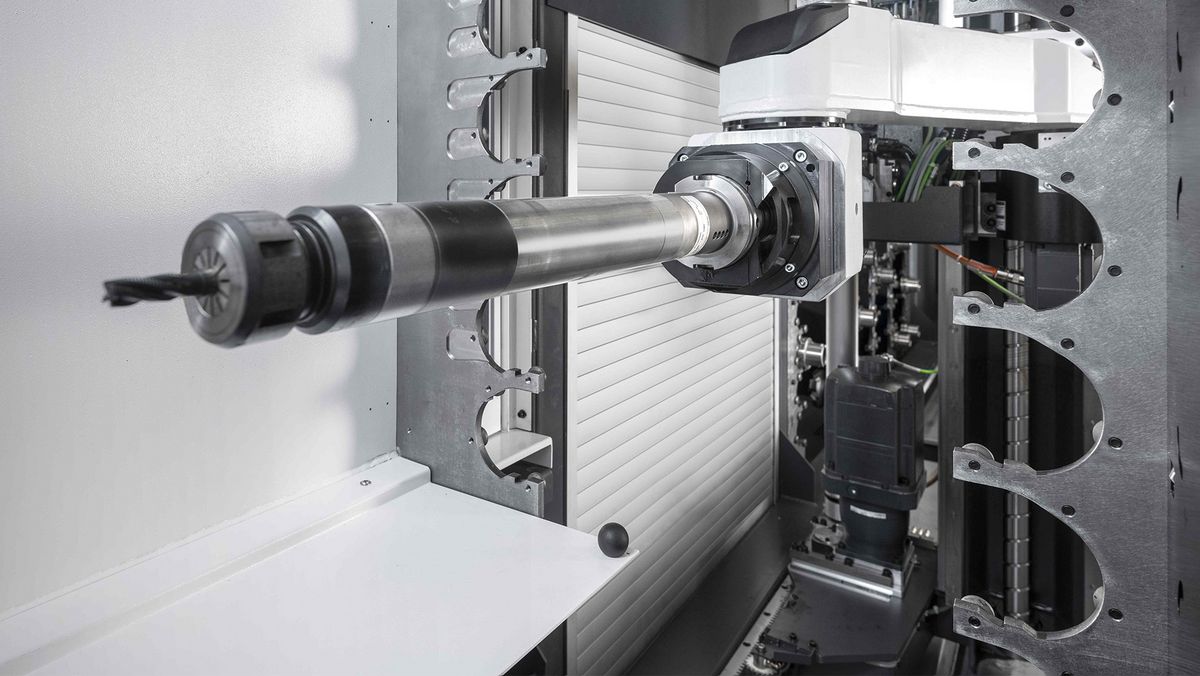

In addition to the HF 3500, HELLER is presenting another technological highlight in the form of the F 5000. This 5-axis machining centre with a direct-drive mill-turn rotary table is designed for the most demanding requirements, such as those encountered in everyday applications in the aerospace, mechanical engineering, and medical technology industries. Thanks to its clevis kinematics and powerful HSK-T-100 motor spindle, even the most complex geometries can be machined in a single setup. This saves time, increases process reliability, and improves precision. The newly developed tool rack magazine with mobile rack is particularly innovative and revolutionizes setup. Tools are prepared in sets and changed while the machine is running. This drastically reduces non-productive times while also reducing the workload for operators. The F 5000 demonstrates how HELLER transforms technological complexity into a clear competitive advantage.

Digital solutions – intelligence that connects

But HELLER doesn't stop at machines and hardware. At EMO 2025, the company will present a comprehensive portfolio of digital and AI-supported services that take the operation of its machines to a new level. With the ASK.me chatbot, HELLER introduces the first intelligent communication interface between humans and machines. Whether for maintenance, error analysis, or status queries, ASK.me understands the language of the operator and provides clear, context-related answers. The chatbot uses the collective knowledge of HELLER and its users and becomes smarter with every interaction.

This is complemented by the HELLER Services Interface (HSI), which creates transparency throughout the entire machine life cycle. Production data is not only collected, but also evaluated using AI and visualized in an understandable form – as text, diagrams, or tables. This reveals optimization potential, enables preventive maintenance to be planned, and helps avoid unplanned downtime. With the myHELLER customer portal, users also have access to spare parts, service information, and an overview of their entire machine park at any time – regardless of location, intuitively, and efficiently.

The SETUP, PRODUCTION, and QUALITY Assist systems also demonstrate how consistently HELLER focuses on the operator. They accompany the operator throughout the entire process chain—from setup to production to quality assurance. This not only increases efficiency, but also enhances safety and ensures quality.

The TOKN Area – Experience, Dialogue, Co-Creation

A special highlight of the trade fair presentation is the TOKN Area. It is much more than just an exhibition space – it is an experience world, dialogue platform, and innovation laboratory all in one. Here, visitors can experience live how HELLER networks processes, visualizes data, and involves customers in the development of new solutions. In interactive sessions, CAD data is transferred to digital twins, processes are simulated, and optimizations are tested – even before they are implemented in real life. This makes it clear that HELLER not only builds machines, but is also a partner that shapes the future together with its customers.

Thorsten Schmidt describes the significance of the TOKN Area as follows: “TOKN is our key to the future. Here we show how we connect technology, data, and people. Customers become not just spectators, but active co-creators. This is co-creation in its purest form.”

The HELLER Suite – An exclusive space for genuine conversations

Alongside the live demonstrations at the trade fair stand, HELLER is opening the HELLER Suite in Hanover. It has been deliberately designed as a retreat for decision-makers – stylish, quiet, and inspiring. In an atmosphere reminiscent of exclusive worlds of experience, the focus is not on machines or technology, but on people and dialogue. Here, ideas can be developed, strategies discussed, and partnerships strengthened. With the Suite, HELLER is sending a clear message: the future is not created by technology alone, but above all by trust and genuine conversations.

Goals of trade fair participation

HELLER has several clear goals for EMO 2025. First and foremost, it wants to make its new brand compass, “Experience sparks Intelligence,” visible and tangible. Customers should feel the transformation of HELLER—not only through machines and services, but through the entire nature of the presentation. In addition, dialogue on an equal footing is a central focus. HELLER is not looking for short-term success, but rather long-term partnerships. Finally, the trade fair also serves to generate leads: new contacts, new projects, and new markets are to be developed.

Voices from the company

Dr. Thorsten Schmidt, CEO: "We stand for precision, intelligence, and partnership. With our innovations, we demonstrate that we not only understand the challenges of tomorrow's manufacturing, but are actively solving them. Automation and digitalization are not a luxury, but the basis for future viability. Our solutions are scalable, intuitive, and economical - exactly what the market needs right now. HELLER is evolving - and our customers are evolving with us. Together, we are shaping a networked, intelligent manufacturing system that sets new standards."

Our location at EMO

In Hall 12, Booth C 70, trade visitors can experience how HELLER combines digital intelligence, automation, and modern mechanical engineering - for greater efficiency, safety, and productivity in manufacturing.